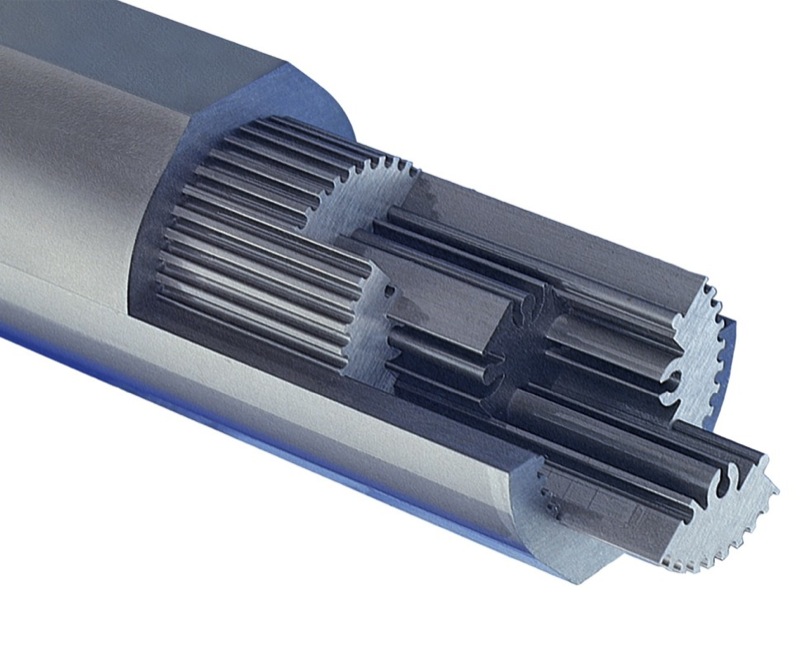

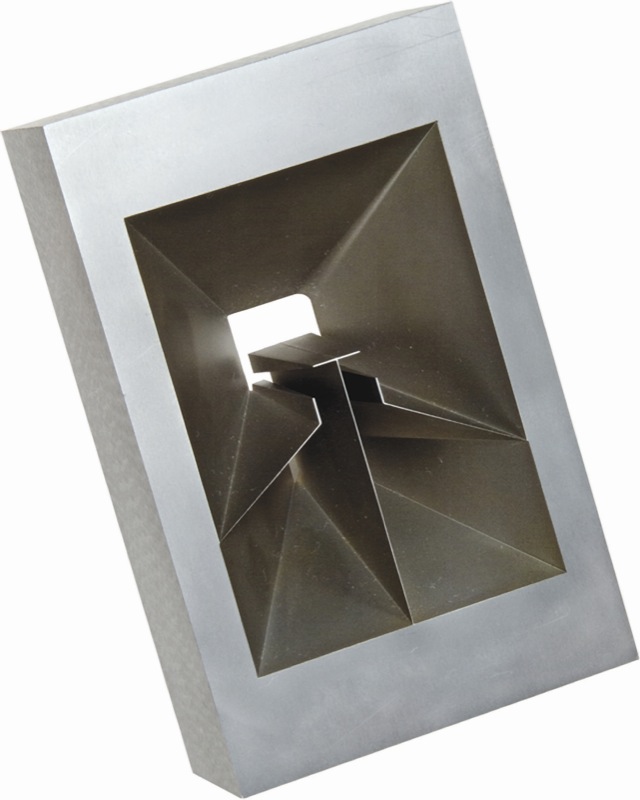

Specialists in wire EDM, CNC Machining

and Extrusion Dies

Profils Précision was founded in the year 2000 and it was built on very solid ground: The vast experience of founder Michel Champagne, who started working in the plastic extrusion sector in 1969 and who also headed the company for 18 years.

The enterprise was founded jointly by Michel Champagne and Mrs. Francine Champagne. At first, Profils Précision made extrusion dies destined exclusively for manufacturers of plastics. Steve followed a similar path: He acquired extensive knowledge and expertise while working in the extrusion sector where he studied all its phenomena with great interest. He joined the Profils Précision team in 2001, where Michel fine-tuned Steve’s knowledge by passing on to the latter his expertise in extrusion die design and machining. This expertise was furthered by the training and experience that Steve acquired in spark erosion cutting and CNC machining. Today, at the helm of Profils Précision, Steve has all the necessary skills to ensure his company’s continued success in this field. He is ably supported in this endeavour by Ms. Caruso, his administrative assistant.

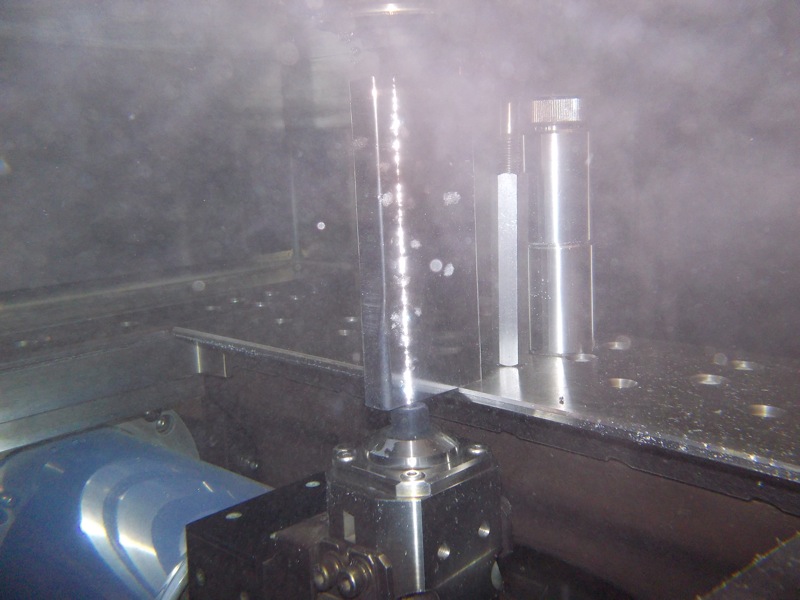

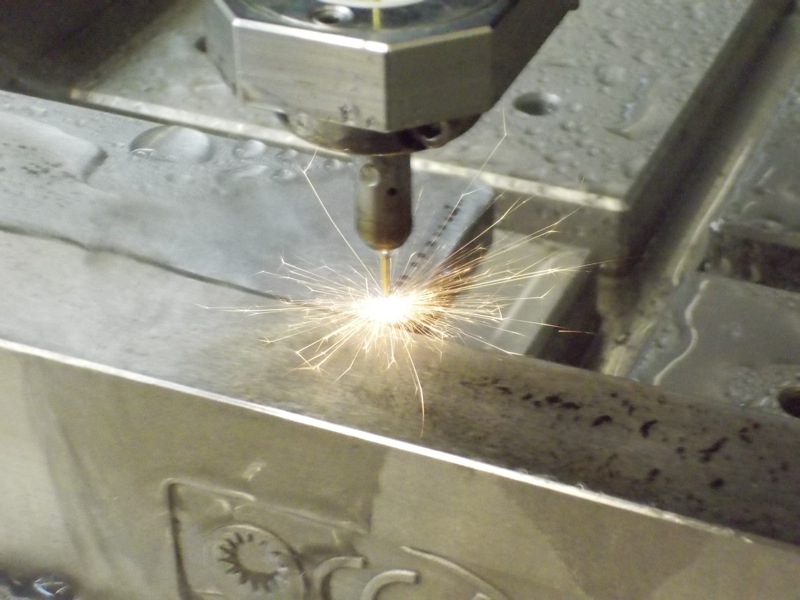

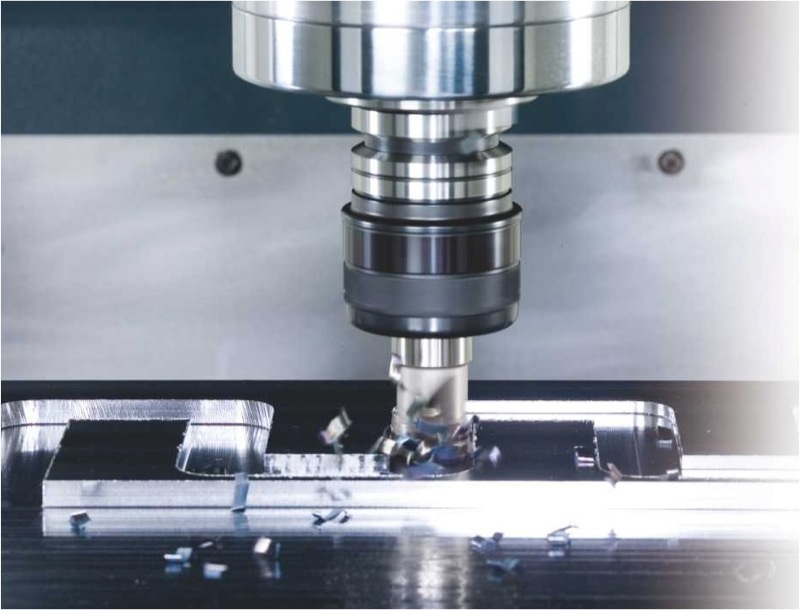

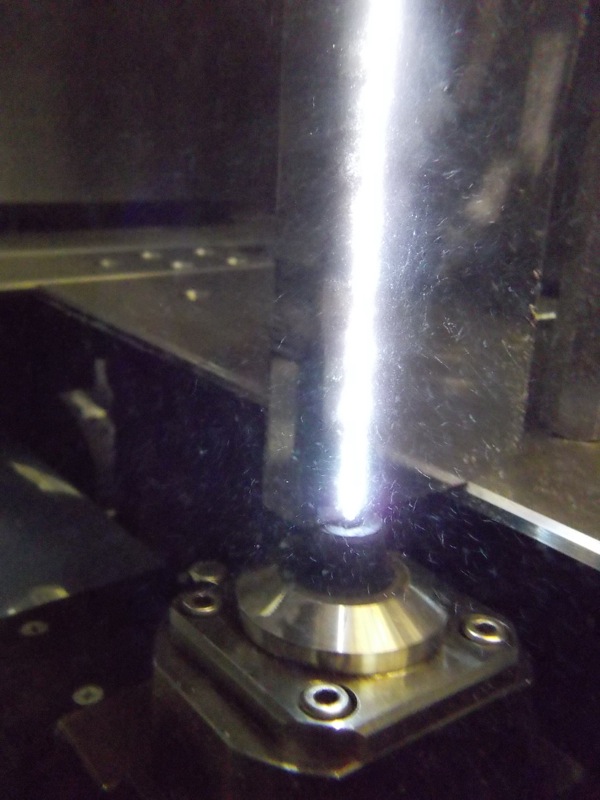

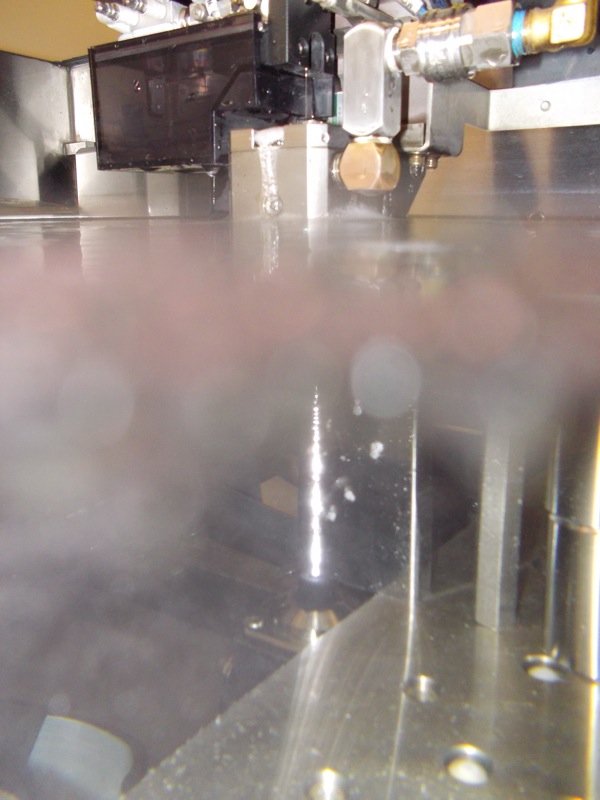

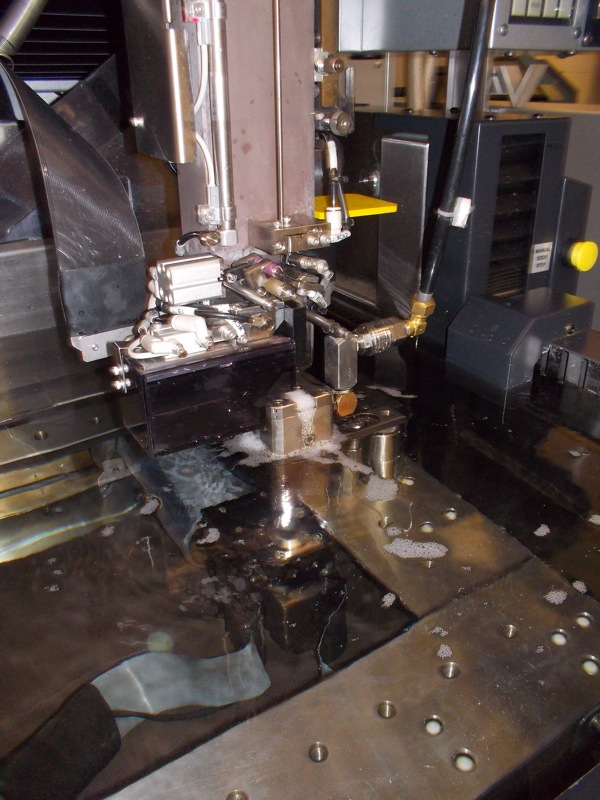

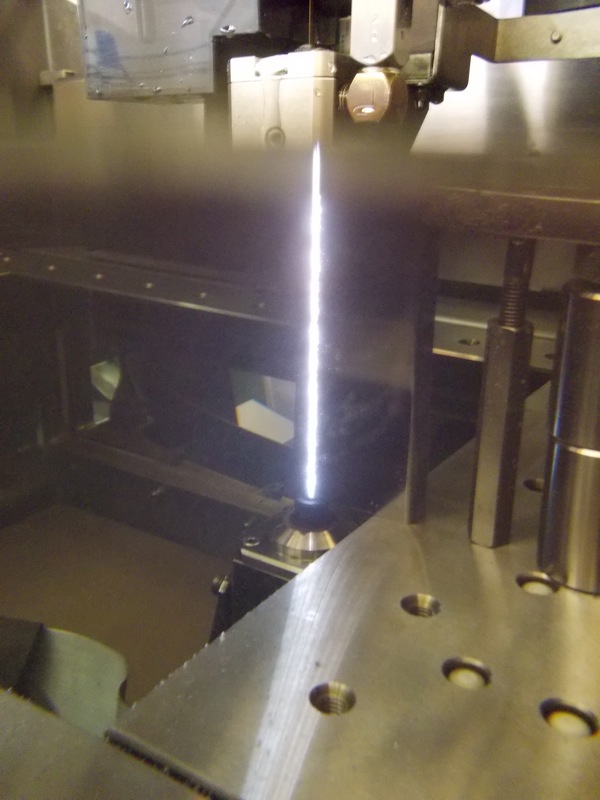

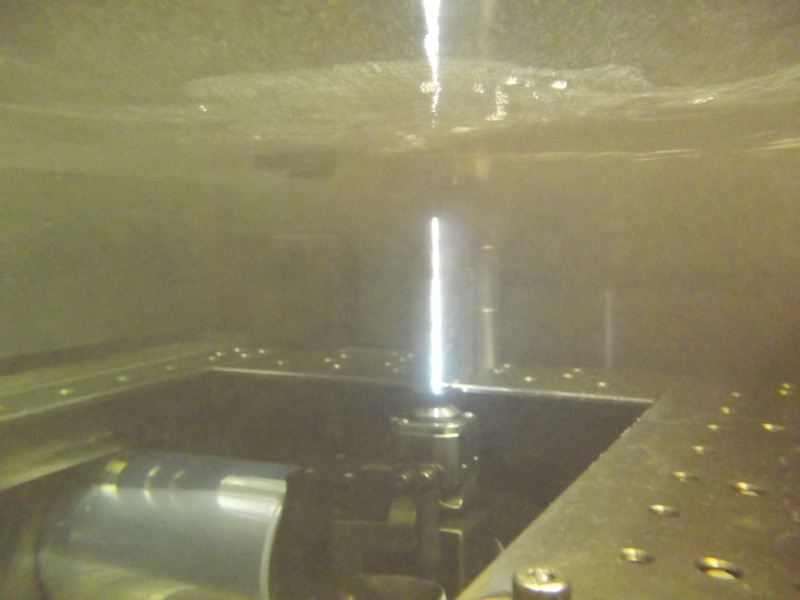

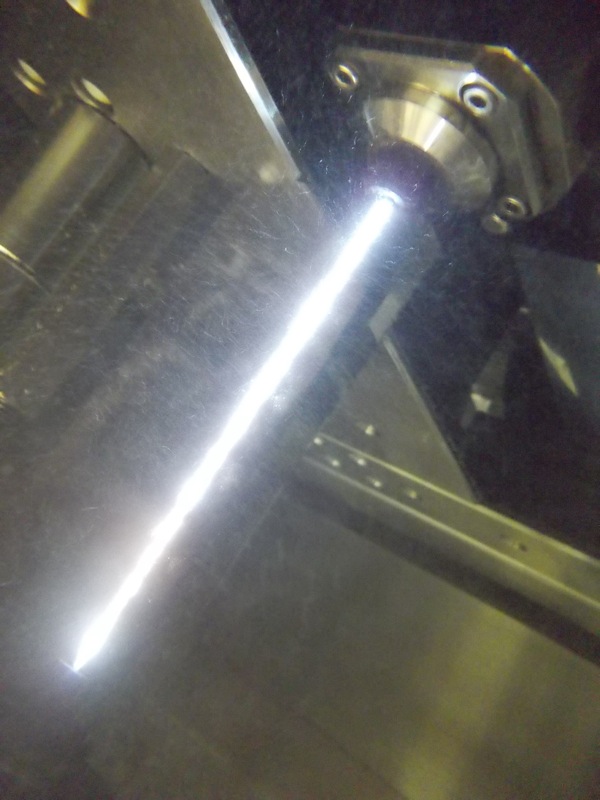

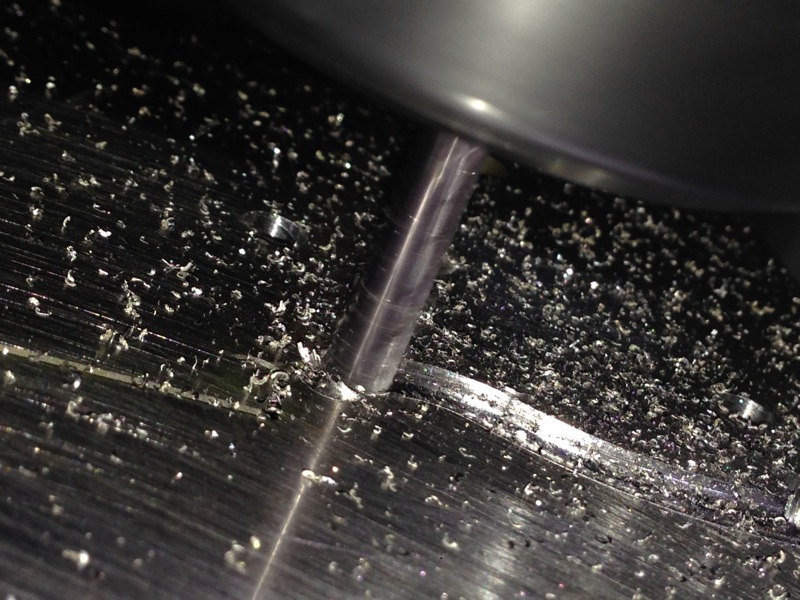

To better respond to the growing demand, Profils Précision recently acquired additional spark erosion cutting and digital control machining equipment for its extrusion die manufacturing processes.

For Experience, Support, Reliability, and Versatility !

To begin, our specialists can ensure the complete design and manufacture of dies and calibrators intended for the plastic extrusion sector. This comprehensive service includes having the client test the finished part. With Profils Précision, you can count on the full support of our team of experts to thoroughly verify your finished product and, if required, make any necessary adjustments.

We are able to guarantee reliable results thanks to the use of equipment at the leading edge of technology. This equipment maximizes the precision of the work while minimizing production time.

Profils Précision is also recognized for its rapid execution and unwavering respect of deadlines.

In all our projects, we begin with careful listening in order to respond efficiently to the unique needs of each client. We adapt our solutions to the great diversity of client requests by offering them the option of using our services in part or in totality. We are also flexible and versatile in processing applications.

In addition, at Precision Profiles, we’re always on the lookout for new developments and technological advances in the production of parts and the finished product itself. We know that this directly affects the time and cost of manufacturing and therefore, the ultimate sale price – and we adjust accordingly! By overcoming challenges, by always assessing all possibilities and solutions, and by investigating, questioning, and probing every aspect of a project, we are able to consistently meet our efficiency standards and achieve your desired results.

In short, Profils Précision ensures efficiency, open-mindedness and, above all, precision in striving to continually surpass itself!